BRETCLB - Intégration automobile et aéronautique

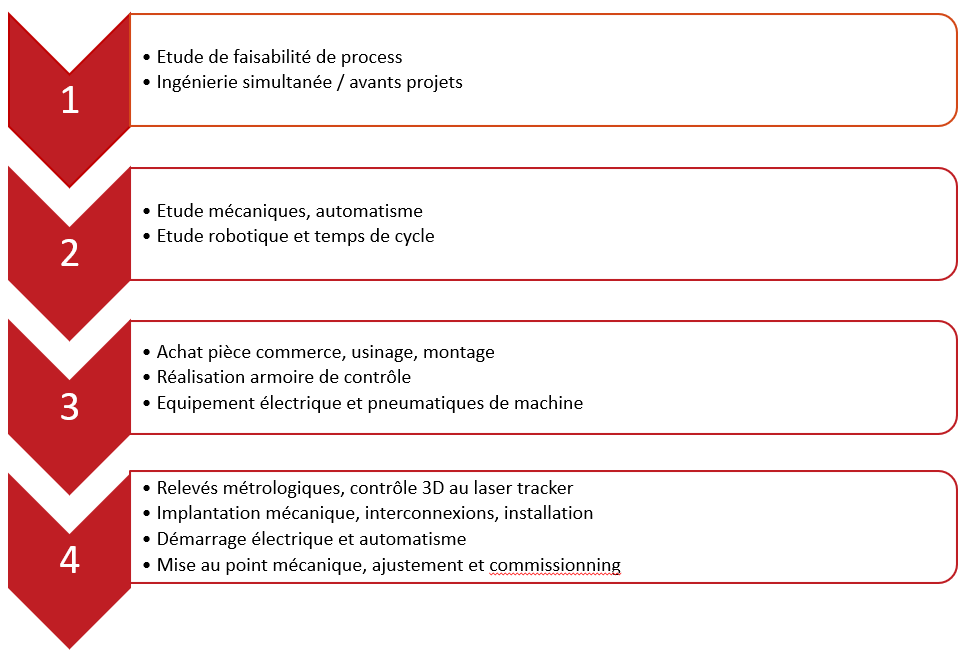

Depuis plus de 40 ans nous sommes spécialisés dans la fabrication de machines spéciales pour l'industrie. Nous accompagnons nos clients depuis la phase d'avant projet jusqu'à la mise au point sur site.

Nous sommes en mesure de travailler en Rang1 pour les grands groupes tout comme en prestation régie ou clé en main en Rang2.

Notre particularité est d'effectuer plus de 90% des projets avec nos ressources internes. Cela permet de parfaitement maîtriser le triptyque Qualité-Coût-Délai.

Notre métier

Domaine d'activité

Les industries dans lesquelles nous sommes le plus actif sont :

-

Automobile

-

Moyens de contrôle

-

Moyens de soudure prototype

-

Ilot robotisé : soudure par résistance, encollage, clinchage, manipulation

-

Outillages de géométrie en BiW, préhenseurs, presses à souder

-

Montage

-

Carry over, mise à niveau d'automate, ajout de diversité dans un flux

-

Ingénierie simultanée (phase 1) de process

-

-

Aéronautique

-

Montage de rectification

-

Montage de géométrie

-

Montage de contrôle

-

Ilot robotisé de tronçonnage, meulage

-

Machine spéciale : banc de contrôle

-

-

Ferroviaire

- Machine spéciale

Nos outils

-

Conception mécanique

- CATIA V5

- Autocad

- Microstation

- Robcad

- Process simulate

-

Automatisme

- Siemens TIA Portal

- Siemens Step7

- Schneider PL7

- See-electrical Expert

- XElec / XFluid

-

Contrôle

- 2x Machine de mesure tri-dimensionelle Stiefelmayer

- Laser Tracker Leica

- Bras de contrôle Faro

- Logiciel Metrolog X4